Metrix DPS Phase Trigger & Speed Applications

The Digital Proximity System (DPS) from Metrix Vibration is used to monitor fluid film bearings in rotating and reciprocating machinery used in various industries. One of the biggest use cases of the DPS is to provide an accurate phase marker or speed system.

Introduction

Vibration monitoring systems are used for monitoring plant equipment in power generation, oil and gas, water and wastewater as well as as in many other industries. The Digital Proximity System (DPS) from Metrix Vibration is used to monitor fluid film bearings in rotating and reciprocating machinery used in these industries. One of the biggest use cases of the DPS is to provide an accurate phase marker or speed system.

Why do you need the DPS Phase Trigger (Once-per-Turn Marker) Solution?

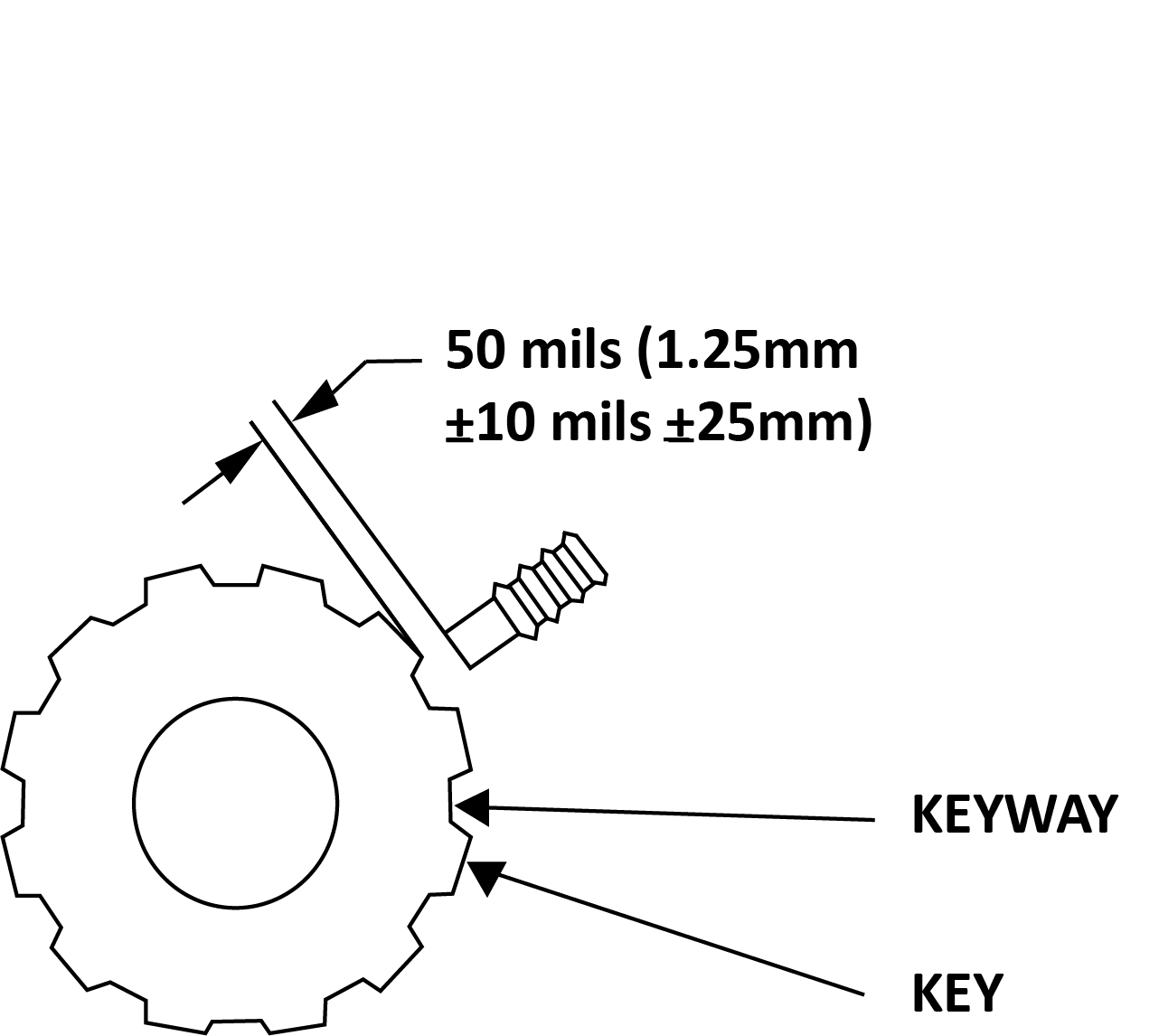

There are many installations where the vibration monitoring system has been rendered virtually useless because of a faulty once per turn phase marker. The faulty phase trigger causes the amplitude and phase to not be reported, or even worse, to be reported inaccurately. Usually the only way to fix a faulty once per turn phase marker is to shut down the machine, open it up and determine the problem.

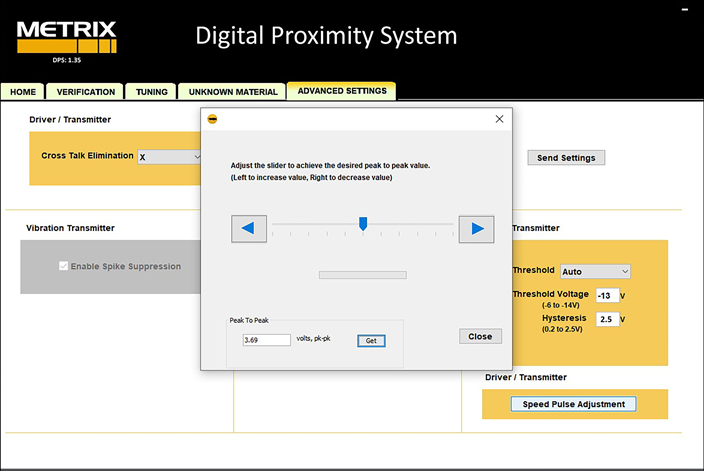

But times have changed! Our Digital Proximity System (DPS) can be used to gain the scale factor to obtain an adequate pulse for the vibration monitoring system to report correct phase and speed values. This advanced speed adjustment feature is available with our free DPS software.

Speed Pulse Adjustment Feature in DPS Software

Why choose the Metrix Speed System?

Only our solution can help you to fix the phase trigger or speed pulse when the machine is operating! There is no other comparable solution available today that can help you fix this problem when the machine is running. Any other solution would likely require you to have unscheduled downtime, or extend your downtime on startup.

Our speed system can go up to four pulses at 100,000 rpm (400,000 pulses per minute).

Why Choose Metrix?

Compatibility:

We are completely compatible with major competitors on a one-on-one replacement basis. You can replace their probes and cables with Metrix probes and cables and their system will work. You can use their probes and cables with our DPS and the system will meet API 670 requirements.

Multiple Advantages:

You can reduce your spare parts inventory by replacing different drivers and transmitters with a field configurable device that easily connects to any proximity probe with a variety of system lengths and target materials. Take advantage of features like Cross Talk Elimination, TightView™, Unknown Shaft Material, SIL and Hazardous Area Ratings.

Lead Times:

And we have unparalleled 5 day lead times so that you can complete your system installation on time without loss of production.

Other Resources:

Datasheets, Manuals & Certifications:

Refer to our various Related Products below which outline the specifics regarding the Digital Proximity System family of products - MX8030 Proximity Probes, MX8031 Extension Cables, MX2033 Drivers, suitable for use with a Monitoring System, and the MX2034 Proximity Transmitters, suitable for use with a variety of Control Systems (e.g. DCS, PLC, SCADA, etc.).

Brochures, Videos & Animations:

You can also browse through our Digital Proximity System brochure, and view our demonstration videos and animations that explain the innovative features of our revolutionary Digital Proximity System.

Contact Us:

Please reach out to Metrix Sales or Technical Support for more information.