Metrix Vibration Monitoring Methodology

Metrix sells value, not just products.

The Metrix Vibration Monitoring Methodology mirrors the Plant’s Return on Investment (ROI) model. With better vibration data collection, organizations save more than they spend.

Introduction

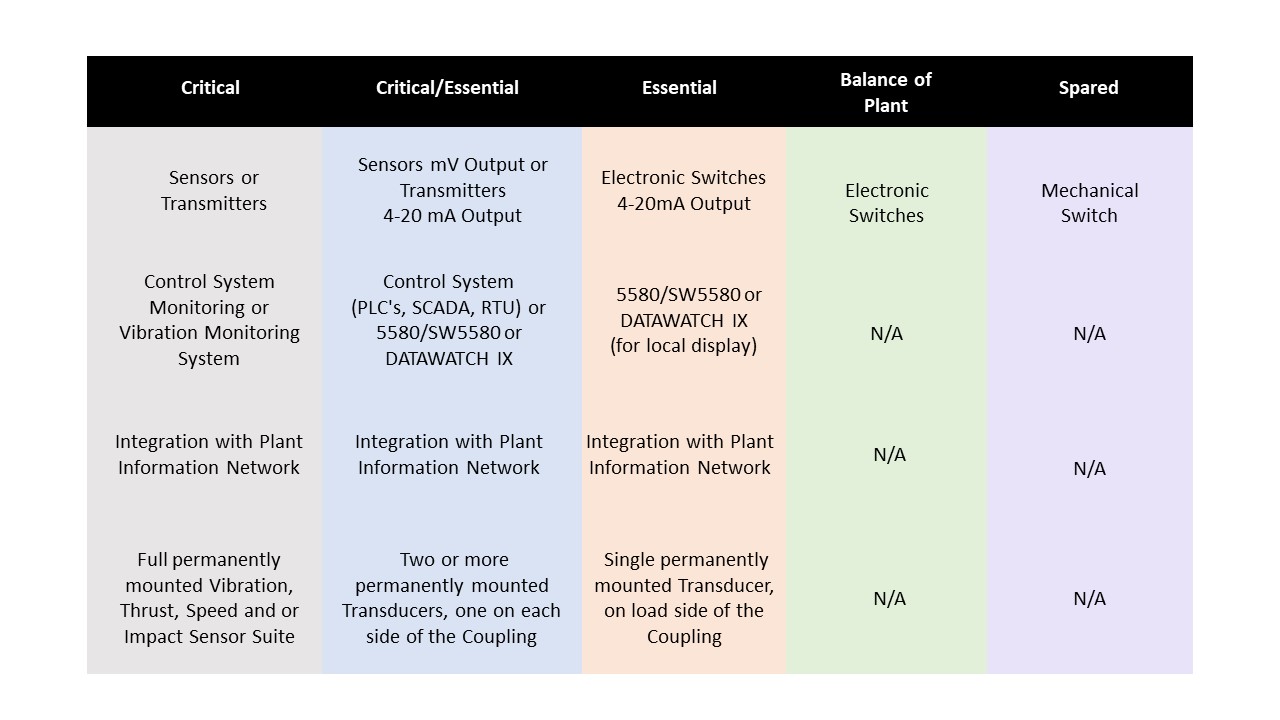

Metrix’s vibration monitoring benefits were designed with the client in mind. Our sensor solutions are important for every operation, but we know that every organization will use them differently. For critical production limiting machines, we advocate sensor solutions that monitor each bearing and throw, thrust, and speed on rotating or reciprocating machinery. For non-critical rotating or reciprocating machinery that only marginally affects plant production, we advocate a minimal sensor solution for monitoring and protection, or depending upon the asset, an electronic or mechanical switch for protection.

Our solutions are structured based on the likelihood of downtime. Different methods of vibration monitoring can protect an organization from economic stress, particularly when it comes to plant shutdowns. We know that the plant not only loses profits when this happens (lost Opportunity Cost = loss of profitable output), it also results in expedited repair, material and labor costs, standby labor costs, quality issues, customer trust/delivery issues, and, most importantly, personnel safety concerns. Our products are not just versatile, they’re also easily configurable to a variety of industrial operations.

Metrix Offerings by Customer Value

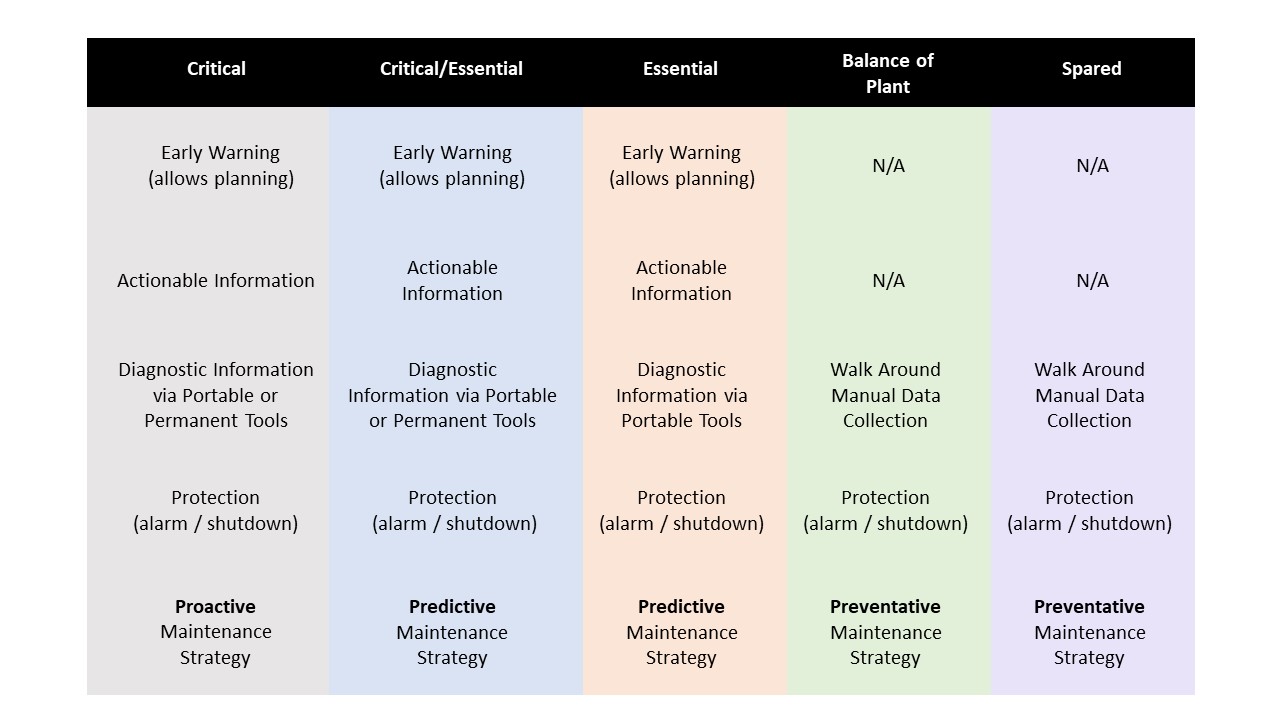

Metrix Offerings by Customer Benefits

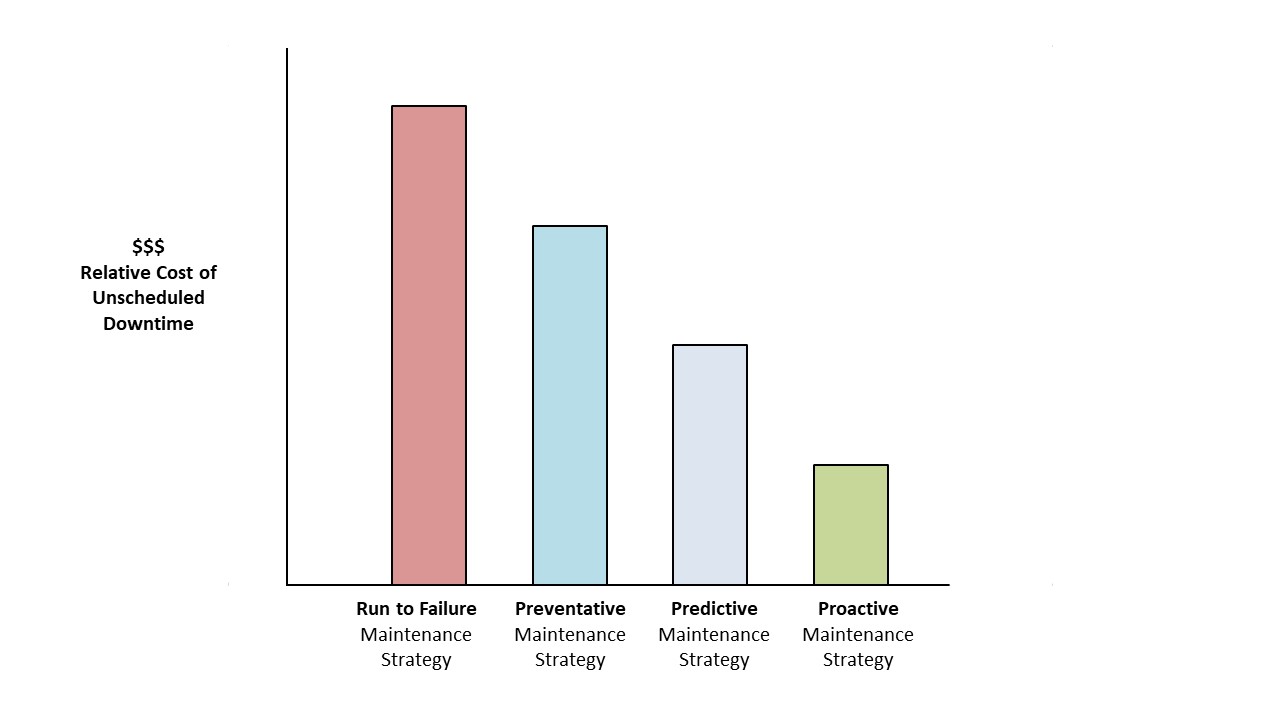

Metrix solutions can reduce unscheduled downtime and expedite repairs. With more reliable equipment, you can improve quality, reduce delivery issues, and cut back on safety concerns.

Rotating and reciprocating machines are managed in one of four ways:

The management of machinery is directly tied to how much value an operation gets from each machine. Vibration monitoring is a way to understand when a machine is beginning to malfunction long before it affects your bottom line.

1. Run to Failure (worst): This is the most expensive way to operate: run the machine until it fails, then replace it.

2. Preventative Maintenance (good): Repairs to the machines are made on a periodic basis, regardless of the machine’s condition. Oftentimes, the preventative repairs are more damaging to the machine than if the machine was left alone — this is the second most expensive way to operate.

3. Predictive Maintenance (better): Repairs to the machines are made based on the condition of the machine. Using predictive technologies like vibration monitoring, thermal imaging, and lubrication analysis, operators can drastically cut back on the costs of maintenance. The key is that operators need a consistent investment in permanent monitoring via transmitters integrated with the existing Control System (PLCs, SCADA, RTUs, and more).

4. Proactive Maintenance (best): Repairs to the machine are made based on the condition of the machine, based on predictive technologies like vibration monitoring, thermal imaging, and lubrication analysis. These tools combine continuous vibration monitoring with data correlation with the plant process parameters of pressure, flow, power level, capacity, etc. This is the most inexpensive way to operate, but it has the highest initial startup cost.

The point of vibration monitoring benefits is to give operators as much insight as possible into their machines. Mechanical failures rarely occur in a vacuum. There are typically dozens of signs before a plant should shut down, but these signs aren’t always noticeable if you don’t have the right vibration monitoring equipment. That’s why it pays to invest in proactive maintenance.

Customers use vibration monitoring to save money!

Customers want to save money, but they need vibration monitoring in order to have a Predictive or Proactive Maintenance strategy. With vibration monitoring, they have a number of choices. From sensors to cable accessories, different methods of vibration monitoring can go a long way to protect the investment of your equipment. We’ll look at the most common that Metrix uses, where they’re applicable, and how the data is intended to be used.

Methods of Vibration Monitoring

1. Walk-Around Periodic Vibration Data Collection (without transient data): This term refers to periodic data collection as a form of standard maintenance and monitoring, and it’s usually complemented with a Metrix vibration switch (mechanical or electrical) to prevent machine failure between readings. Typically, these readings happen around once a month, so operators have sufficient information to determine relevant trends.

2. Walk-Around Vibration Data Collection (with transient data): This collection method is completed after a problem has occurred. If the machinery is malfunctioning or a Metrix vibration switch has forced a machine offline, technicians will cover the plant to determine the root cause of the issue.

3. Continuous Vibration Monitoring (without waveform and transient data): The more information you have, the more patterns you can identify. It not only helps operators reduce the number of shutdowns, it also reduces the number of false alarms. With this method, operators will usually integrate monitoring with alarm and shutdown capability to prevent machine failure. Metrix 5580 / SW5580 with Metrix Sensors, DATAWATCH IX with Metrix Transmitters, or Metrix Transmitters connect directly to the Control System, so operators can be certain they’re working with the most accurate data.

4. Continuous Vibration Monitoring (without waveform and transient data, with process data correlation): This form of vibration monitoring takes the process one step further. Alarm and shutdown capability prevent machine failure, and the Metrix 5580 / SW5580 with Metrix Sensors or DATAWATCH IX with Metrix Transmitters can be integrated by Modbus TCP/IP over Ethernet to the Plant Information Network. As an alternative, Metrix Transmitters are connected directly to the Control System which has been connected to the Plant Information Network.

5. Continuous Vibration Monitoring (with process data correlation): Routinely integrated with alarm and shutdown capability to prevent machine failure and easily identify trends. This method also provides the ability to perform machinery diagnostics by having the proper transducer suite on the machine. The vibration, thrust, speed and/or impact data is incorporated with the Control System process data. The more information there is to correlate between events, the more confident operators will be when they’re making decisions about what to replace, repair, and reconfigure.

6. Continuous Vibration Monitoring (with waveform and transient data with process data correlation): Generally incorporated with alarm and shutdown capability, this method prevents machine failure and easily identifies trends based on standard process conditions. One of the most important vibration monitoring benefits is the ability to define what’s normal. In addition, operators perform machinery diagnostics on demand. A Vibration Monitoring System (e.g. AS7000, Setpoint, BN 3500, etc.) with Metrix sensors can be integrated via plant process data historian.

Why Monitor Rotating and Reciprocating Machinery for Vibration?

Customers will employ vibration monitoring collection for a number of reasons:

1. Safety of personnel and surrounding equipment.

2. To prevent catastrophic failure of equipment.

3. To trigger alarms and shutdowns before equipment is damaged.

4. To provide early warning of equipment problems so maintenance can be planned.

5. To avoid unplanned maintenance and unplanned plant/facility shutdowns.

6. To save money!

The Method of Vibration Monitoring is determined by the ROI, measured in terms of Compounded Annual Rate of Return (CARR).

Rotating and Reciprocating machinery Return on Investment (ROI) is determined by a number of factors, the biggest of which are the Average Cost of Repair and the Lost Opportunity Cost due to unscheduled downtime. Depending upon the process the Lost Opportunity Cost can far outweigh the Average Cost of Repair. The solution Metrix provides should provide a (ROI) of two times the cost in less than three (3) years for avoiding just one Unscheduled Repair, for a Compounded Annual Rate of Return (CARR) of 26%. Here are some examples:

150 Megawatt Combined Cycle Gas Fired Power Plant Example

In order for this power plant to operate, the critical equipment must be in good condition. For example, the Gas Turbine, the Steam Turbine, their associated generators, the Feed Pump, the condensate pumps, the cooling system, etc. all have to be in working order before operations can commence.

The margin on 1 megawatt-hour (MW-hr) of electricity is a minimum $45 USD / MW-hr, sold to wholesale customers (this is a $0.045 USD per kW-hr rate). So, one hour of unscheduled downtime equates to a Lost Opportunity Cost of $6750 (150 MW-hrs/hour x 1 hour x $45/MW-hr = $6750). One day of unscheduled downtime results in a Lost Opportunity Cost of $162,000 per day ($6760/hour x 24 hours = $162,000) Customer Value = Repair Cost + Unscheduled Downtime = + $162,000 minimum per day.

Note: Components within the combined cycle plant may be redundant or, if unavailable, may reduce plant capacity. This applies to the condensate pumps, cooling water pumps, cooling tower fans, etc., meaning they have less of a financial impact on the plant. For example, let’s assume that if a cooling tower fan is out of commission, the plant capacity is reduced by 5%. That would mean that the Customer Value is 5% of the values calculated above or $8,100 per day ($162,000/day x 5% = $8,100).

In other words, the Gas Turbine, the Steam Turbine, their associated generators, and the Feed Pump may easily justify Full Metrix Transducer Suite of Sensors (XY Bearing Vibration, Thrust, Speed, and/or Impact) with full integration to the Plant Information System, whereas the condensate pumps, cooling water pumps and cooling tower fans would justify the one or two Metrix transducers and possibly the Metrix 5580 / SW5580 or DATAWATCH IX Solution integrated to the appropriate Control System and Plant Information Network.

Sensor solutions are so versatile now that power plants can easily use them in even the most out-of-the-way areas. This allows technicians to get the flexibility they need without having to put themselves in harm’s way to get the job done.

Small Natural Gas Pipeline Reciprocating Compressor Station Example

In a Natural Gas Pipeline Compressor Station with a Capacity of 92,000,000 cubic feet per day (2,600,000 cubic meters per day), 100% of the flow is through the reciprocating compressor. The margin on 1000 cubic feet of Natural Gas is $0.48 USD for sales to an Industrial Customer. One day of downtime results in $44,160 in Lost Opportunity Cost ($0.48 x 92,000,000/1000 x 100% = $44,160). Customer Value = Repair Cost + Unscheduled Downtime = + $44,160 minimum per day.

Note: If the pipeline capacity is 10 times larger (which is not uncommon for larger pipelines), the Lost Opportunity Cost is 10 times higher.

This small Natural Gas Pipeline Reciprocating Compressor would easily justify the Metrix 5580 / SW5580 with Metrix Sensors or Metrix DATAWATCH IX / Transmitter Solution integrated into the Plant Information System. This is as opposed to a VMS with Metrix Sensors with full integration to the Plant Information System, which may be hard to justify for such a small facility.

Other larger reciprocating compressor stations could easily justify a full Metrix Suite of Sensors with full integration into the Control System and Plant Information Network. Metrix is committed to providing as many different methods of vibration monitoring as possible, so plants of different sizes don't have to overspend for effective protection.

Why Choose Metrix?

Metrix provides value by reliably providing information when you need it, at the least possible cost while at the same time giving you early warning of machine malfunctions. Metrix Methodology makes vibration monitoring easy by recognizing the fact that most of your machines are running well. You only need to worry about exceptions.

For example, only our solution can help you fix a phase trigger when the machine is operating. There is no other comparable solution available today that can help you fix this problem when the machine is running. Any other methodology would likely require you to have an unscheduled downtime or extend your downtime on startup.

We can reduce your spare parts inventory by our unparalleled five-day lead times so that you can complete your system installation on time without loss of production. Take advantage of our SIL and Hazardous Area Ratings. Reach out to us, we look forward to serving you.