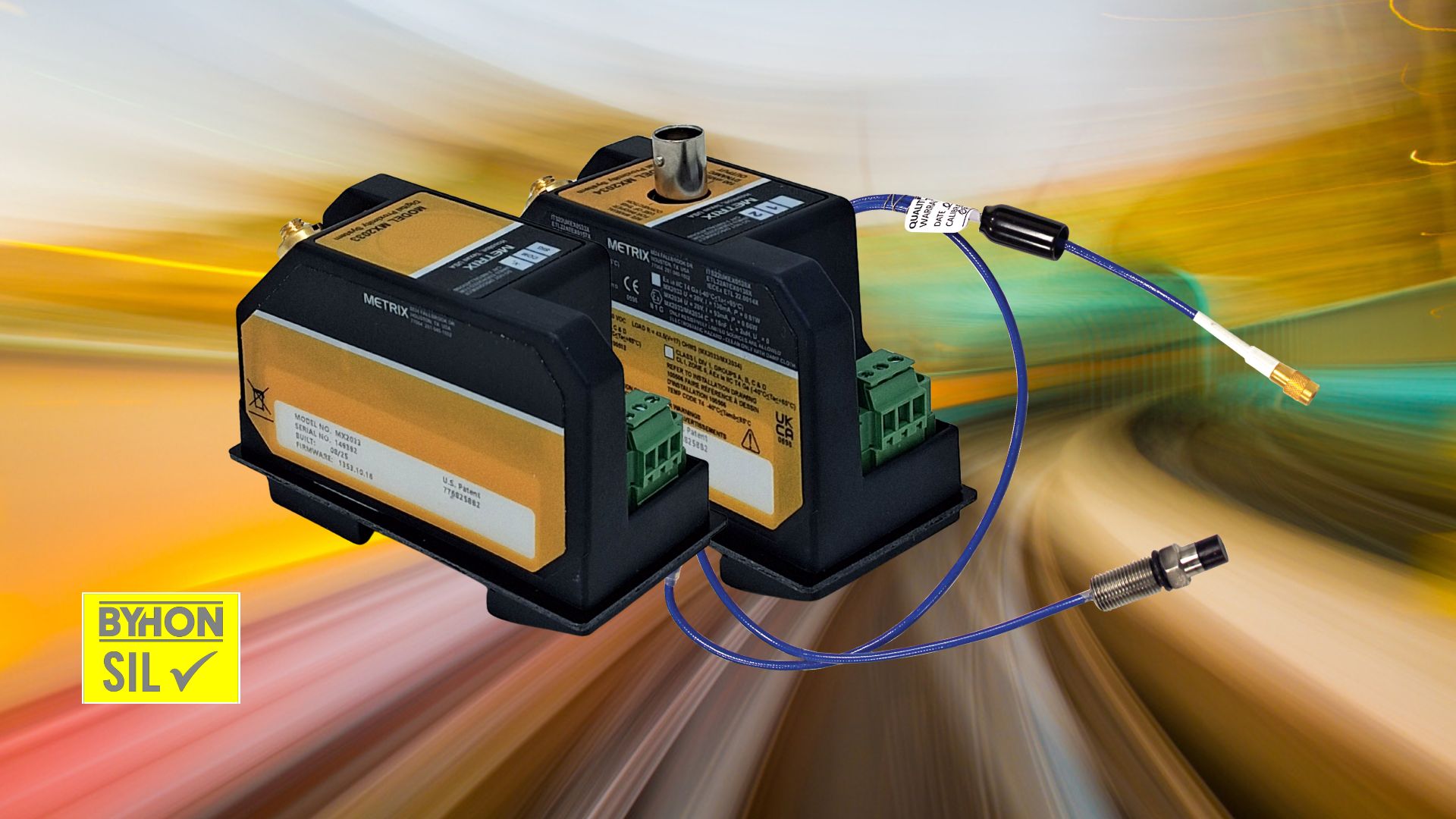

Digital Proximity System (DPS) Infographic

The vibration monitoring systems used on integrally geared centrifugal air compressors consist of proximity transmitters into the machine’s control system. It is just one of many machine types where vibration transmitters are an economical, reliable, and suitable approach to machinery monitoring and protection.

But with many vibration transmitters on the market, why would you choose Metrix?

Here are 16 compelling reasons…

- 1983 – We invented the vibration transmitter, introducing both proximity (Metrix 5465) and seismic (Metrix 5461/5463) versions.

- 1996 – The transmitter concept proved so successful that the API 672 standard was revised to accommodate transmitters as the default and preferred method for monitoring integrally geared air compressors.

- 2003 – We invented the world’s first digital proximity transmitter – the TXR (radial vibration) and TXA (axial position).

- 2012 – We introduced the world’s first software-configurable proximity transmitter – the Metrix Digital Proximity System (DPS).

- 2016 – We invented TightView™ technology, allowing standard 5mm and 8mm probes and cables to be used in tight clearance applications, eliminating the need for special “narrow field” probes, cables, and signal conditioners. Simply compensate the probe’s curve for reduced clearances using the DPS configuration software, freeing you to use the same probe family across every machine in your plant.

- 2018 – We invented cross talk elimination features that assign different frequencies to two adjacent probes, stopping their fields from interfering with each other and giving erroneous readings. It is perfect for 672 machines where small shaft diameters are common and maintaining sufficient probe tip spacing can be especially challenging.

- 2019 – We introduced software configurable spike suppression to ensure that electrical transients and other sources of intermittent, non-periodic electrical interference do not affect the 4-20mA transmitter output, preserving machine protection integrity.

- Our easy-to-use DPS configuration software allows any probe, cable length, target material, and proximity measurement (radial vibration, axial position, speed/phase) to be addressed with a single, universal transmitter. One size truly does fit all. You can experiment with it right now - just download the software and run in simulation mode to explore all of its powerful capabilities.

- The DPS is available in both a transmitter version (MX2034) and driver version (MX2033) - providing the same world-class flexibility and software configurability for applications where you need a conventional 3-wire API 670 device instead of a loop-powered transmitter. And, the same software is used to configure both types of devices!

- Not only does the DPS give you flexibility of measurement types, full-scale ranges, target materials, and cable lengths – it gives you flexibility of manufacturers. If your machine already has embedded probes from another supplier, the DPS can support them. Our own probes and cables are even interchangeable with our major competitors' cables!

- Loop-powered transmitters are energized with +24 Vdc, meaning the polarity of the buffered output is inverted and must be “flipped” to do proper diagnostics and to be consistent with monitoring elsewhere in your plant that doesn’t use transmitters. Other manufacturers require the use of special, external adapters for polarity inversion. Metrix makes it much simpler - a software-configurable option.

- The DPS system carries worldwide hazardous area approvals, meaning it can be used on machines beyond just air compressors, no matter the process and no matter the environment.

- The DPS can be used as part of a Safety Instrumented System (SIS) – it features SIL certification!

- Older, analogue transmitter designs lock you into special probes for API 672 machines and inflexible signal conditioners that require different transmitters for radial vibration, thrust, and speed/phase. But the complexity doesn’t stop there. Each full-scale range option also requires a different transmitter! We spell value differently: less complexity where one size fits all.

- Have you ever tried to get to a manual from some suppliers? Their website might as well be a castle with the drawbridge raised. Not with Metrix. Every manual, every datasheet, every approval cert, every diagram – all of it – is online here on our website where you can instantly access it, saving you precious time and money.

- The MX2034 provides permanent wiring terminals, allowing access to the raw signal from up to 100 ft (30m) away. Other manufacturers limit you to no more than 16 ft (5m) of cable, making connections to patch panels and external systems impractical without incurring the additional cost and complexity of line amplifiers.