Digital Proximity System (DPS) Provides Perfect Solution for Power Plant Upgrade

Introduction

A power company in the Midwest USA recently evaluated multiple vendor solutions for upgrade of their existing vibration instrumentation on one of their unit’s main steam turbine generators, induced draft fans and boiler feed pump trains. Having already made a substantial investment in transitioning the power plant from a coal to gas-fired boiler, and with significant life left in the unit, improved vibration monitoring capabilities were justified to ensure reliable operations.

Metrix worked closely with the end user, system integrator and their machinery protection and condition monitoring system partner to define, propose and deliver a turnkey solution. Ultimately, Metrix’s Digital Proximity System (DPS) was selected for upgrade of the existing proximity probe systems and to retrofit the boiler feed pump trains to monitor vibration, position and phase.

Challenge

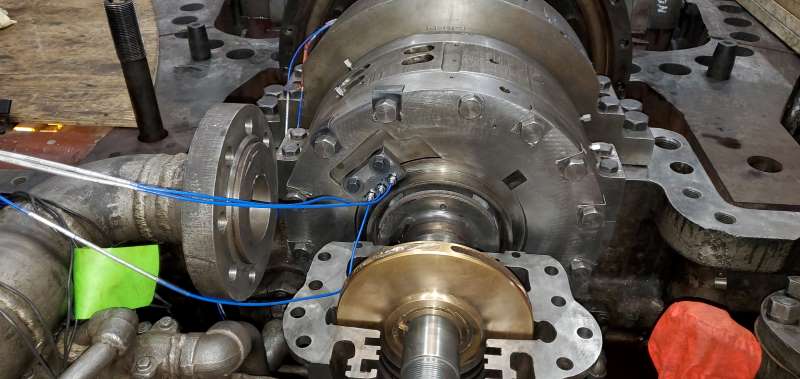

Although the steam turbine generator and induced draft fans had previously been retrofitted with proximity probe systems, they had been installed for 20 years. Replacements were becoming more challenging to come by, and often carried long lead times. In the case of the boiler feed pump trains, neither the motors or pumps had existing proximity probe systems, and as a result, retrofit was necessary to achieve best practice monitoring. A variety of probe system configurations were required, including various case diameters and lengths, electrical lengths, linear ranges and in some cases, Metrix’s TightView applications.

Specific to the boiler feed pump trains, and almost anytime a machine retrofit is required for proximity probes, it was not known until the machines were disassembled exactly what probe configurations would be required. As a result, it was critical to the end user that probes systems could be acquired in a timely manner once the design for installation was complete to avoid delays to machine reassembly and plant startup.

Solution

Metrix’s DPS was an ideal solution for upgrade of the existing vibration instrumentation and retrofit of the boiler feed pump trains. With a vast number of probe configurations, all of the existing transducer systems were easily upgraded without the need for additional brackets or adaptation to existing probe mounting provisions. Furthermore, for retrofit of the boiler feed pump trains, DPS Drivers, Probes and Cables were supplied in a timely manner to meet the end user’s schedule. Finally, as DPS is configurable, it allowed for field configuration changes in the case of the boiler feed pump phase triggers which enabled DPS Drivers, originally configured for 80 mils of linear range, to be increased to 160 mils of linear range. Without this field configurability, the Drivers would have to be reordered, which would have caused delays to machine reassembly and startup.

DPS proved to be the right solution for the project, and enabled the customer to leverage readily available and state of the art vibration instrumentation within their new machinery protection and condition monitoring solution.

Benefit

Through a close working relationship with the end user, system integrator and monitoring system partner, Metrix delivered quality and flexible instrumentation on time and at a competitive price. Metrix stayed out of critical path during the unit overhaul and deployed reliable instrumentation that will be leveraged to protect and monitor the health of the end user’s machinery for years to come.