Proximity Probe Mounting Brackets, Probe Holders and Junction Boxes

Junction box at a power plant

The right housing for a proximity sensor depends upon how the proximity sensor is going to be installed. In some installations, you may not even use a housing because of space considerations. It is certainly less expensive to not use a housing and go with a forward mount probe, with armored cable, to the driver or transmitter (oscillator demodulator) junction box. Due to the industrial environment where we find proximity sensors, a more durable installation is oftentimes required. This blog will cover the different types of mountings used for proximity sensors, considering mounting factors like environment, mounting location, and economic considerations, all of which need to be kept in mind before you buy.

Types of Proximity Probe Mountings (Internal vs. External)

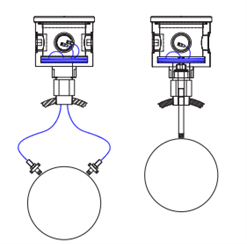

There are two basic types of proximity probe mountings. They are Internal Probe Mounts and External Probe Mounts. Internal means the proximity probe is not accessible once the machine is assembled. External means that the proximity probe is accessible after the machine is assembled. This blog will be focused on External installations, but we will briefly discuss Internal installations.

Internal / External Proximity Installations

Internal Probe Mounts are usually done with brackets that are bolted to the non-moving side / structure of the machine as shown in the below picture.

7646 Internal Probe Bracket

With an internal probe mount, the probe is locked in place by two means. After the probe is properly gapped, the bolts that connect the bracket to the fixed part of the machine are torqued such that the probe may not be removed (approximately 66-inch pounds (7.5 N-m)). Then the probe body jam nut is torqued to 100-inch pounds (11.3 N-m).

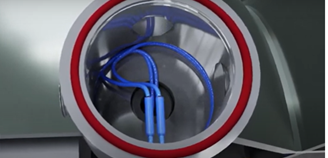

It is best practice to run the probe cable from the internal mounting location to a local junction box via a feedthrough. This way the probe connector and extension cable connector are away from any fluid that may be inside the machine. For most applications, this feedthrough does not penetrate a pressure boundary. Where the probe does have to penetrate the pressure boundary, a high-pressure feedthrough may be necessary. With a few notable exceptions, the proximity probe connector to the extension cable connector should be kept dry and protected in order to prevent ground loops.

Probe to Extension Cable Connection with Connector Protectors in Place

Electrical Junction Boxes for Proximity Sensors

For proximity systems, junction boxes start where the probe exits the machine, with another at the connections for proximity drivers or transmitters, and then finally where the field wiring connects to the Vibration Monitoring System or the Control System. The junction boxes protect the cables and connections from moisture, dust, and physical abuse. They also provide a location for organization and labeling. This allows for fewer errors when servicing the sensors and less uncertainties in the event of an emergency.

For internal installations, Metrix recommends using the 5498JB because it includes a feedthrough to get the probe cables out of the machine and it provides a location where one can connect the probe to the extension cable in a protected environment. It also provides room for the connector protectors to put over the probe to extension cable connection, preventing ground loops. The feedthrough provides an internal rubber grommet that when properly installed holds the cable tightly and provides a moderate pressure boundary up to 3 bar (50 psi).

5498JB Picture

5498JB Picture

For external installations, Metrix has several options. The 5497PM Probe Mounting System provides the most flexibility and ease of use of our external probe mounting options. The 5497PM has three different connection head types, depending upon environmental factors. The durable plastic connection head is meant for general purpose use applications. The aluminum connection head comes with the ground screw and provides a very rugged junction box. The 316 stainless steel connection head is meant for applications where, not only rugged installations are required, but also a more corrosion resistant solution is necessary. Internally to the 5497PM, there is a pressure boundary that utilizes two O-rings. The O-rings provide a moderate pressure boundary of up to 3 bar (50psi).

5497PM Probe Mounting System

5497PM Probe Mounting System

The 5495 Forward Probe Mount Mounting System with the 5498JB Connection Head provides a very economical way to have an external forward probe mount with an easy way to connect the extension cable. The 5495 Forward Probe Mount provides for a probe to easily be inserted and gapped into place. The jam nut is used to compress a gasketed washer to make for a leak tight seal up to 3 bar (50 psi).

5495 Forward Probe Mount with 5498JB Connection Head

For high pressure applications, we recommend using the 5499 Heavy Duty Reverse Probe Mount Housing. Model 5499 ruggedized housing provides physical protection for probe to 1000 PSIG (6.89 MPa). It facilitates faster and more accurate probe gap setup and maintenance with separate coarse adjustment and vernier fine adjustment mechanisms with VERNIGAP®. Disassembly of the integral conduit union allows adjustment access. Maximum insertion depth: 7.4 in.

5499 Heavy Duty Reverse Probe Mount Housing

5499 Heavy Duty Reverse Probe Mount Housing

Equipment Cable Routing

Metrix has a wide variety of mounting options for proximity sensors. The first step is determined whether the proximity sensor is going to be internal to the machine or external, meaning accessible externally from the machine. Once you’ve made the decision what kind of mounting system you need, you will have to determine how to protect the probe connector to extension cable connector connection. This is usually done in our round junction box presented above. It’s important within the junction box that you put the connector protector booties on the probe to cable connection to ensure that a ground loop will not form. It’s important to keep the probe to cable connection dry to prevent ground loops. Note: In certain internal mounting situations, the probe to cable connection can be fully submerged in water, oil, LNG, etc., but the fluid needs to be clean and uncontaminated to remain non-conductive. Also, for submerged connectors, some sort of barrier will need to be put in place to prevent the fluid from wicking through the extension cable to the proximity driver or transmitter. See the Metrix 5494 Feed Through Extension Cables or the Metrix 6-Pin High Pressure Feedthrough (99541-100-KIT).

5494 Feed Through Extension Cables

5494 Feed Through Extension Cables

6-Pin High Pressure Feedthrough (99541-100-KIT)

Environmental Conditions

An electrical junction box will need to withstand certain seismic forces, but it also has to withstand severe temperatures, humidity, and moisture. Whether it's indoors or outdoors, it's important to choose an enclosure that's as rugged as it is compatible. Plus, consider the location of the enclosure and how the indoor or outdoor environment could interfere with proper connections and placement.

Driver / Transmitter Junction Box

The junction box used for proximity drivers and transmitters can be the same type of box. It should be chosen for the type of service it can encounter. For example, most weatherproof housings used for proximity system drivers and transmitters are NEMA 4 / IP 65, as in the picture below. One wants to protect the drivers and transmitters in an appropriate enclosure.

7876 Weatherproof Housing

Industry Standards

Regardless of which industry standards apply to your industry, proximity sensors may be highly specific to their applications. This means that the probe holders and enclosures used in practice should be rated for the application. Metrix provides a wide variety of probe holders, brackets and enclosures to meet your needs.

When proximity sensors are properly protected, they can provide early and accurate warnings for your most valuable machinery. A solid proximity system installation will provide years of service and allow you to make effective decisions regarding the condition of your machinery.

How to Find the Right Electrical Junction Box

The Metrix website lists our probe holders, brackets, and junction boxes necessary for an effective proximity system installation. If you have questions about which junction box is best for which application, the staff at Metrix can help you answer individual questions. From IP ratings to corrosion resistance, the answer isn't always as straightforward as it may seem. With the right partners, you can start buttoning up your site operations, so you can depend on the systems that keep your business open and your employees safe.