Vibration Monitoring in Reciprocating Compressors: Ensuring Optimal Performance and Longevity

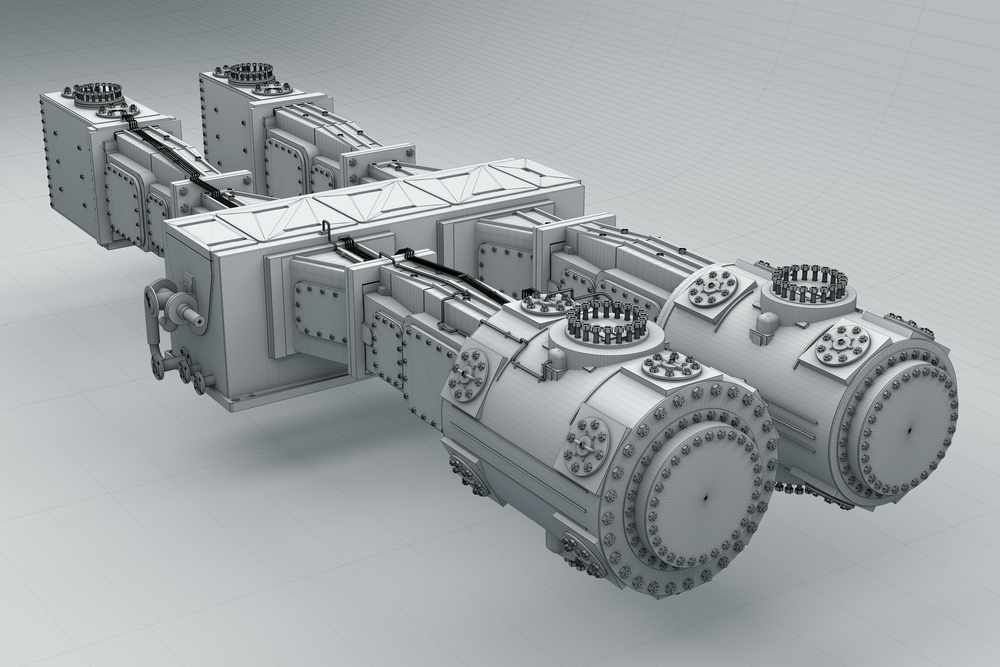

3D model of a four-throw reciprocating compressor

Reciprocating compressors have emerged as a cornerstone of industrial processes across various sectors, from oil and gas to manufacturing. As industrial operations grow in scale and complexity, ensuring the optimal performance and longevity of reciprocating compressors has become critical. At the heart of this effort lies vibration analysis – a powerful tool for maintaining and optimizing these sophisticated machines.

Reciprocating compressors operate in demanding environments, constantly subjected to cyclic loads, pressure variations, and diverse operating conditions. These factors create unique vibration patterns that, when properly monitored, can reveal crucial information about the compressor's health and performance. By implementing robust vibration monitoring programs, industrial operators can detect potential issues early, optimize maintenance schedules, and significantly extend the lifespan of their assets.

As reciprocating compressors continue to evolve in design and capacity, the role of advanced vibration monitoring becomes increasingly crucial. From valve diagnostics to crankshaft health assessment, these techniques offer unparalleled insights into compressor performance. By leveraging cutting-edge vibration monitoring technologies, industrial operators can not only preempt costly failures but also optimize their assets for peak efficiency in the dynamic and challenging realm of industrial compression applications.

Understanding Reciprocating Compressor Vibration

Reciprocating compressors experience complex vibrations from various sources. Impulsive forces from piston movement, valve operations, mechanical interactions in the crankshaft and connecting rods, structural responses of the frame, and process-related oscillations all contribute to the vibration profile. These forces interact in intricate ways, creating a unique vibration signature for each compressor.

These vibrations, while inherent to operation, can significantly impact compressor performance and longevity. Excessive vibrations accelerate wear, reduce compression efficiency, and potentially lead to catastrophic failures. Understanding these vibration patterns is crucial for maintaining optimal compressor efficiency and preventing unexpected downtime.

Monitoring reciprocating compressor vibration presents unique challenges. The cyclical nature of operation and varying load conditions complicate traditional monitoring techniques. Harsh industrial environments and the compact design of compressors further compound data acquisition and sensor placement difficulties. These factors necessitate innovative approaches to vibration monitoring and data interpretation.

Despite these obstacles, vibration monitoring remains crucial for compressor health assessment. It provides critical insights into component conditions, enabling proactive maintenance strategies and performance optimization in dynamic operational conditions. By leveraging advanced vibration techniques, operators can significantly extend compressor lifespan and maximize operational efficiency.

Monitoring Key Reciprocating Compressor Components

In reciprocating compressor vibration monitoring, certain components demand particular attention due to their critical role in compressor operation and their susceptibility to wear.

Crankshaft and Connecting Rods: These components support the entire piston assembly and are subject to substantial cyclic loads. Vibration monitoring of the crankshaft and connecting rods can reveal early signs of wear, lubrication issues, or misalignment. Metrix employs a velocity sensor or transmitter at each end of the crankcase to assess problems with the crankshaft and employs impact monitoring on the crosshead to monitor for looseness from the crankshaft through the connecting rods and to the piston rod. These measurements allow maintenance teams to plan interventions before minor issues escalate into major failures.

Valves: The valves, often considered the heart of a reciprocating compressor, are particularly prone to wear-induced issues. Common problems include valve plate wear, spring fatigue, and seat damage. Advanced vibration analysis can detect subtle changes in valve impact frequencies and opening/closing patterns, often weeks or months before a failure occurs. Metrix has found that using an impact sensor on the crosshead is an effective means of detecting valve problems that are more significant than normal wear. This early detection capability is crucial for preventing catastrophic valve failures, which can result in extended downtime and significant repair costs.

Piston and Cylinder Assembly: The piston and cylinder assembly, responsible for the actual compression process, plays a vital role in compressor efficiency and reliability. Vibration monitoring of piston rings, cylinder walls, and rider bands can detect issues like insufficient lubrication, wear, or gas leakage. Metrix takes advantage of rod drop and rod vibration monitoring, utilizing the Metrix Digital Proximity System to detect piston and cylinder problems. These problems, if left unchecked, can lead to suboptimal compression performance or even complete compressor shutdowns.

By focusing on these critical components, industrial operators can prioritize their monitoring efforts and maintenance resources effectively. This targeted approach, backed by data-driven insights from strategically located sensors, forms the cornerstone of a robust predictive maintenance strategy in the industrial compression sector.

Predictive Maintenance Strategies in Reciprocating Compressors

Vibration analysis forms the cornerstone of effective predictive maintenance strategies in industrial compressor operations. By leveraging the insights gained from comprehensive vibration monitoring, operators can shift from reactive or time-based maintenance to a more efficient, condition-based approach.

Key elements of a robust predictive maintenance strategy include:

Data Integration: Combining vibration data with other parameters such as pressure, temperature, and performance metrics provides a holistic view of compressor health. This integrated approach enhances the accuracy of fault predictions and helps prioritize maintenance activities.

Trend Analysis: Tracking vibration patterns over time allows for the identification of gradual degradation in components. By establishing baseline vibration signatures and monitoring deviations, maintenance teams can intervene before minor issues escalate into major failures.

Risk-Based Maintenance: Not all components are equally critical or prone to failure. A risk-based approach, informed by vibration analysis, allows operators to focus resources on high-risk or high-value components, optimizing maintenance efforts and budgets. Metrix has found the most important sensors to install are impact sensors on the crosshead, followed by rod drop / rod vibration monitoring, and then monitoring velocity on the crankcase for crankshaft related faults.

Condition-Based Maintenance Intervals: Compressors can be serviced based on their actual condition rather than adhering to fixed maintenance schedules. This approach minimizes unnecessary downtime and extends the life of components that are performing well. The minimum sensor suite for a condition-based maintenance approach on a reciprocating compressor, is to have impact monitoring on each crosshead, either by an impact transmitter or accelerometer, two velocity transmitters or two velocity sensors located at opposite ends of the crankcase, and rod position monitoring located at each packing gland for each cylinder, monitoring both rod drop and rod vibration. The transmitter solution would go to a control system, and the vibration sensor solution would go to a monitoring system.

Predictive Analytics: By using trend analysis and predictive algorithms, one can process vast amounts of vibration and operational data to forecast potential failures weeks or even months in advance. This foresight enables proactive planning of maintenance activities, reducing both costs and downtime.

By implementing these strategies, industrial operators can realize significant benefits:

● Reduced maintenance costs

● Minimized unplanned downtime

● Extended machine lifespan

● Optimized spare parts inventory

● Improved overall machine efficiency and production output

The success of predictive maintenance in industrial compressor operations underscores the critical role of vibration analysis in the manufacturing and process industries, driving operational excellence and supporting continued productivity and sustainability.

The Future of Reciprocating Compressor Vibration Monitoring

As industrial processes continue to demand higher efficiency and reliability, the importance of advanced vibration monitoring in reciprocating compressor maintenance cannot be overstated. The techniques and strategies discussed in this article form the foundation of modern industrial compression management, but the field is rapidly evolving.

Looking ahead, we can expect to see further integration of artificial intelligence and machine learning algorithms in vibration analysis. These technologies promise to enhance our ability to detect subtle changes in compressor behavior, predict failures with even greater accuracy, and optimize maintenance schedules in real time.

Additionally, the advent of more sophisticated sensor technologies and the Industrial Internet of Things (IIoT) will likely lead to more comprehensive and continuous monitoring capabilities. This could potentially allow for real-time adjustments to compressor operation based on vibration data, further improving efficiency and longevity.

For industrial operators and maintenance professionals, staying abreast of these developments will be crucial. Implementing robust vibration monitoring programs today not only ensures optimal compressor performance and longevity but also lays the groundwork for adopting future innovations in this field.

By leveraging the power of vibration monitoring and predictive maintenance strategies, the industrial compression sector can continue to drive down costs, increase reliability, and play an ever-larger role in enhancing productivity and sustainability across various industries. The integration of advanced vibration monitoring technologies promises not only to preempt costly failures but also to optimize assets for peak efficiency in the dynamic and challenging realm of industrial compression applications.

As we move forward, the synergy between vibration analysis, predictive maintenance, and emerging technologies will undoubtedly shape the future of reciprocating compressor management, driving innovation and operational excellence in industrial processes worldwide.